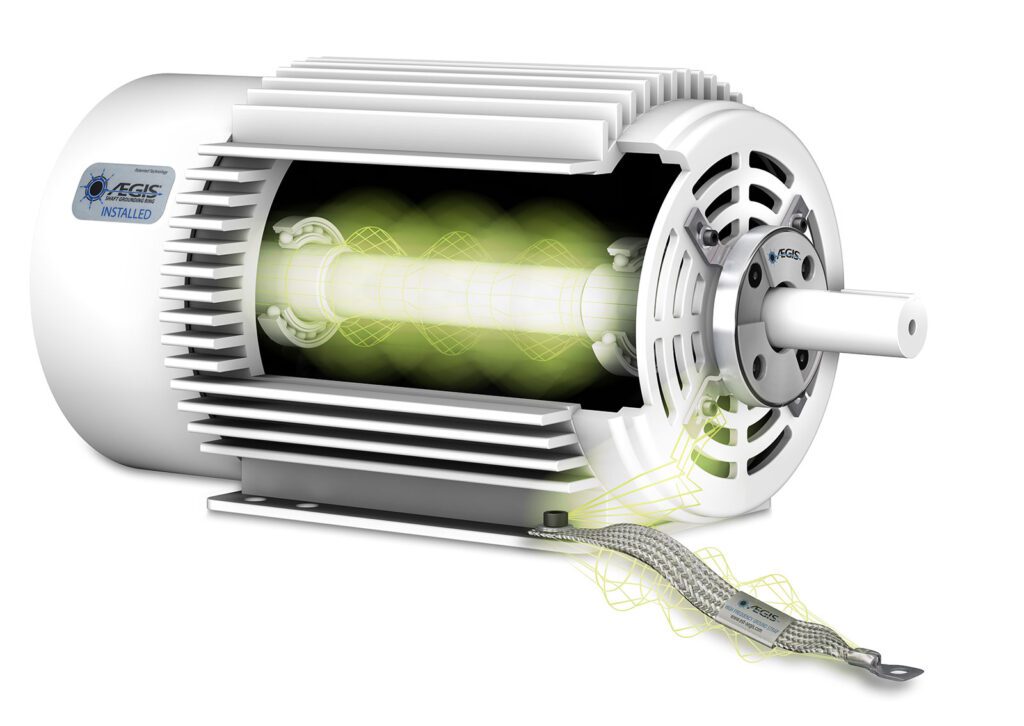

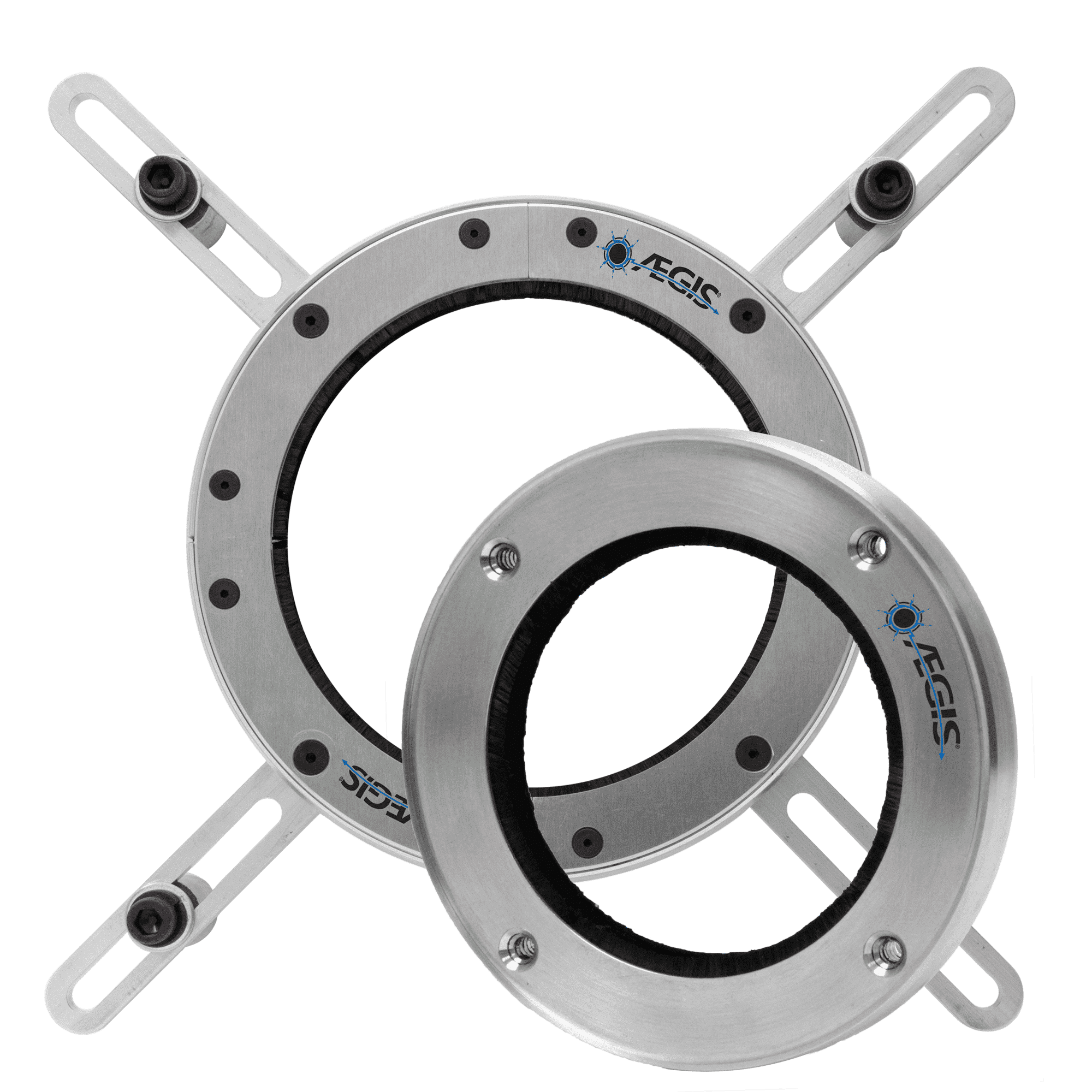

Electro Static Technology’s AEGIS® Shaft Grounding Rings are used in millions of motors across the globe to prevent bearing damage and failure.

Electric motors run by variable frequency drives, or VFDs, are at risk of shaft voltage that can lead to premature bearing failure. Learn how the unique design of our AEGIS® Rings free you from the frustration and expense of unnecessary downtime caused by electrical bearing damage.