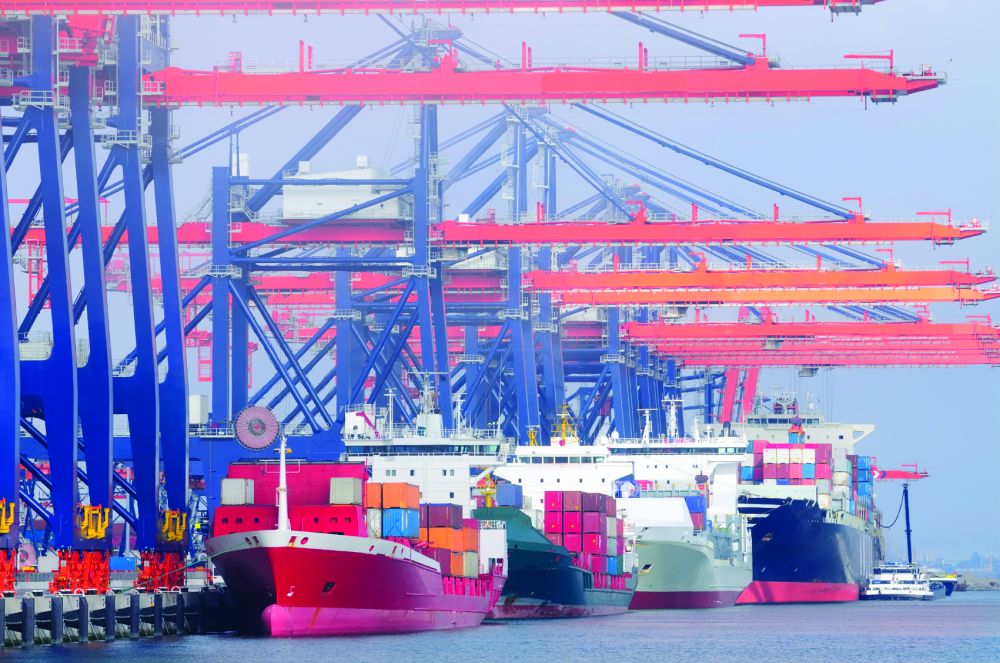

Operational disruption and downtime are a problem for any chemical or other industrial plant. When paper mills, steel-making facilities, or oil and gas producers can’t get product out, it not only creates a loss in immediate revenue, but it allows competitors to step in as a more reliable source.

Protecting electric motor bearings should be part of your organization’s resilience plan for the continuity of operations. AEGIS® Rings are used to help minimize these disruptions and have helped protect companies everywhere from unplanned downtime.