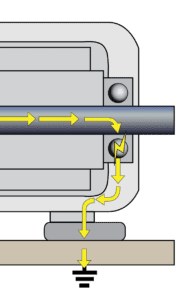

Bearing currents are high-frequency currents that are caused by voltage on the motor shaft, which drives a discharge current through the motor bearings. This is rarely a problem in electric motors operating on line voltage. But variable frequency drives (VFDs) put out pulse width modulated voltage, which can be a big problem for inverter-fed motors.

When operated by VFD, the power to the motor is a series of positive and negative pulses instead of a smooth wave. Therefore, the input voltage is never balanced because the voltage is either large and positive or large and negative, with rapid switching between plus and minus states in all three phases.

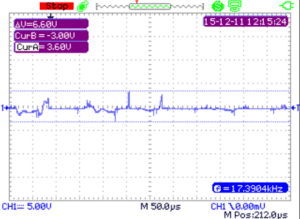

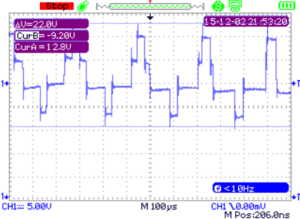

The average voltage between the three phases is called common-mode voltage. It usually has a “square wave” or “6 step” voltage waveform.

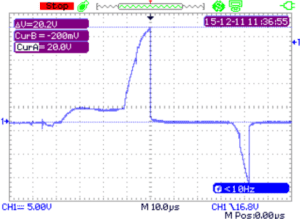

The two destructive types of bearing current in well-grounded VFD-fed motors are capacitive EDM current and high-frequency circulating current.